Projects just keep coming our way!

The most recent one to start with us is coming to us from Eldorado, Texas, a small city in the western Hill Country. Now, as folks who’ve lived in the area can tell you, we may not get a lot of rain in our part of the world, but when it does come, it’s like to come in abundance–and with company, namely hail. In Kerrville, we’ve had hailstorms that left the town coated in little ice pellets, standing a foot deep in some places, and many’re the folks who’ve had close encounters with quarter-sized chunks of ice coming from the sky. (It ain’t comfortable.) As might be imagined, such storms–and we’re always glad of rain–wreak havoc on windows, including such stained glass pieces as our soon-to-start project, the Frey Repair.

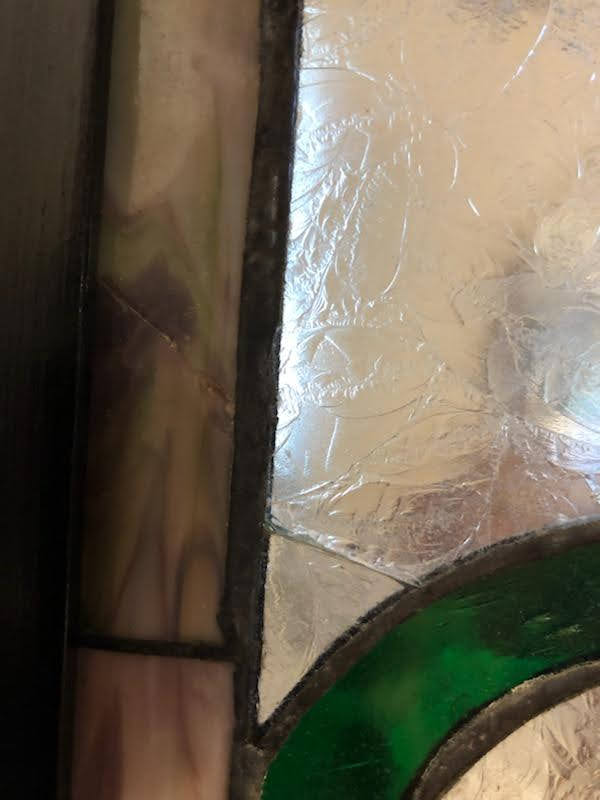

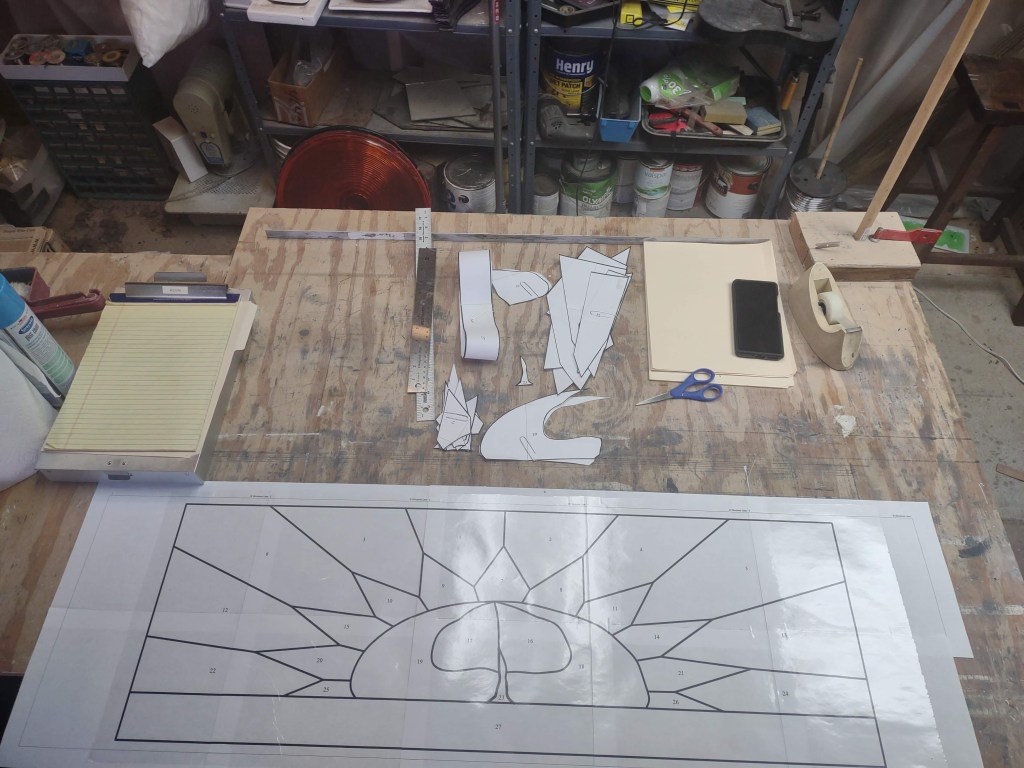

It’s clear even from these photos that there’s work to do; several panes need replacing, including one that seems to’ve had a hole punched clean through it by a particularly ornery hailstone, and there might be more to find once we get a good look at it in our shop. The window needs a good cleaning, too–but between getting that and the repair, when we get it back to the client, it’ll be a glorious little bit returned to another Hill Country town!

We’d love to hear from you. Please, give us a call at 830-890-1509, or message us via our “Contacts” page or the form below to see what all we can do for you!

And, for your writing needs, get in touch with Elliott RWI!